8.

Service Fuel Burners

- Own personnel

- 24 hour Readiness

- Experience

- Spare parts

- Credentials

- Official Authorization

- Efficiency

Global Service for boilers, fuel and industrial burners:

Also available for boilers and systems from other manufacturers

Official periodic tests

- Inspections and obligatory pressure tests of boilers

- Mandatory annual thermal fluid analysis

- Gas and Liquid Fuels facilities (Light oil, Heavy Oil, ...)

Including:

- Combustion analysis

- Service and adjustment of burnerss

Maintenance

- Maintenance service (predictive, preventive and corrective)

- Telemanagement

- Repair and spare parts supply of burners

- Combustion chambers: adjustment of combustion air, draw, temperature

- Refractory

- Steam boilers cleaning of inner parts (water and flue gas area)

- Continuous filtration system for thermal fluids at hot temperatures

- Refurbishment and modernization of boilers

- Tubes substitution (Retubing)

- Boiler coils

- Fixed modular ladders with protections

- Troubleshooting, repair and spare parts

- Supply and change of Thermal Fluid

Engineering:

- Studies of technical and economic feasibility

- Design of turn-key plants

- Energy audits

- Thermal and hydraulic balances

- Customized designs

- Rationalization and energy saving

Systems:

- Complete steam boiler rooms

- Piping, control valves

- Alkaline chemical cleaning, passivation and formation of magnetite

- Vessels

- Stack

- Liquid fuel: Light oil, Heavy oil (IP-03)

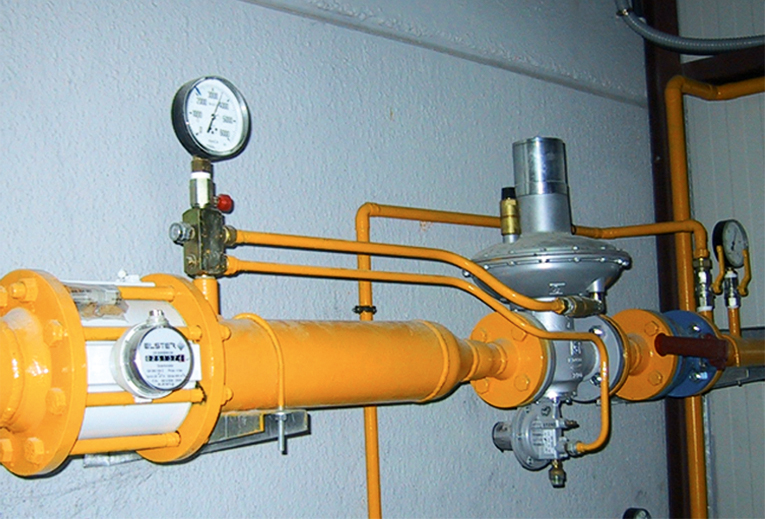

- Gas fuel at low, medium and high pressure

- Change of fuel in existing boilers

- Natural gas regulation and measuring, regulation groups and burner ramps

- Industrial gas meters

- Jacketed lines for asphalt and viscous products

- Secondary circuits for temperature control

- Heat exchangers and auxilliary elements

- Monofluid Systems (heating – cooling)

- Modifications to existing facilities

- Increase of indirect surveillance intervals from 2 hours to 24 hours or 72 hours supervision

Electrical control panel:

- PLC Automation systems

- Data saving and SCADA monitoring and control

Energy efficiency:

- Heat recovery

- Economizers, water preheaters, combustion air

- Burner modulation with O2 y CO continuous analysis

- Inverters in feed pump motors and burner ventilator

Audit to facilities:

- Legalization projects

- Ultrasonic thickness measurement

- Boiler efficiency optimization and heat exchange process

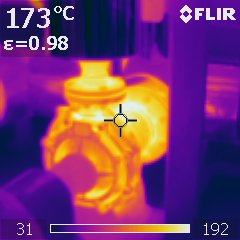

- Infrared thermography (temperature profiles).

- External fluid flow measurement

Biomass:

- Biomass storage, loading and heaters feeding

- Multicyclonic separators with high efficiency.

- Continuous discharge of ashes and slag

- Baghouse Dust Collector